• SH&E

is a line management responsibility. Ownership and accountability for SH&E

performance is embedded in the line at all levels and Line Managers are

responsible for providing SH&E leadership and for development and

implementation of SH&E management plans for their areas of

responsibility.

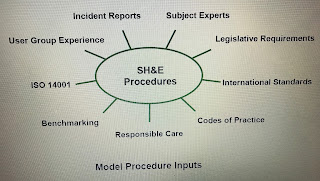

Next we need

to look at set of Model procedures.

The SH&E Model

Procedures provide detail on what has to be done to implement the SH&E

Policy and the SH&E Standards.

The Model Procedures are

used to facilitate compliance and capture best practice. They cover the full

range of SH&E activities and standard model procedures have been developed

by experts in the field (assisted with a range of inputs – see diagram below).

There are over 100

standard model procedures. Businesses are required to prioritise their

implementation of the Model Procedures based on a risk profile of their

activities and hence they logically address the most serious risks first. It is

a long-term goal to achieve and sustain compliance with the Key Requirements of

all the applicable Model Procedures.

The purpose of the prioritisation exercise is to give

sites some focus and allow them to proceed with their SH&E management in a

logical, risk-based manner, in order to develop a manageable program for

implementation of the Model Procedures. This is an effective way to better

utilise SH&E resources and avoid the dilution of the attention required to

manage significant risks that results from resources being spread across too

broad a range of activities.

Each Model Procedure

identifies the issues relating to a topic and describes practical controls to

be applied.

The Model Procedure Suites

are indexed as below:

• SH&E Management

• Safety

• Environment

• Engineering

• Health

Will discuss this further….

No comments:

Post a Comment